To Make a Living

And Sings at his Work

By Reinhart Knudsen

A quarter of a century ago, O. B. Dawson, who had been a promising music student at the University of Oregon, forsook hopes and possibilities of a great vocal career in favor of the forge and the hammer and tongs of the ornamental iron worker.

Now he ranks well up among creators of wrought iron work in the Pacific Northwest, but music remains a not altogether lost love, and he still sings—at his work, and among his family and close friends.

While young, as a blacksmith's assistant, Dawson received so much encouragement from his friends for his singing, that he secretly took a few lessons from an instructor. He did so well that he later enrolled at the Egan school of drama in Los Angeles which in 1921 awarded him a two year scholarship. Then Dawson studied under numerous instructors: Arthur Hubbard, tutor of the notes Negro tenor, Roland Hayes; Lazar Samoieloff, and from 1925 to 1926, under Madame McGrew, the University of Oregon's own opera director.

For eight or nine years Dawson was a professional singer in Los Angeles with local opera companies. He did considerable work in musical prologues in theatres before the coming of the "talkies."

"Although music was my chosen procession I found it difficult to make a living at it," says Mr. Dawson, "so I turned to iron-working, the trade I had picked up in my first working years."

In Portland Dawson set up his own shop, but with the coming of the WPA, he found that his work opened newer and greater fields of opportunity than he had ever realized before.

Throughout the state were men, many well over 50 years old, who displaced as blacksmiths, stood a slim chance of ever again entering the private employment. Yet with a little training, these men made excellent ornamental iron workers

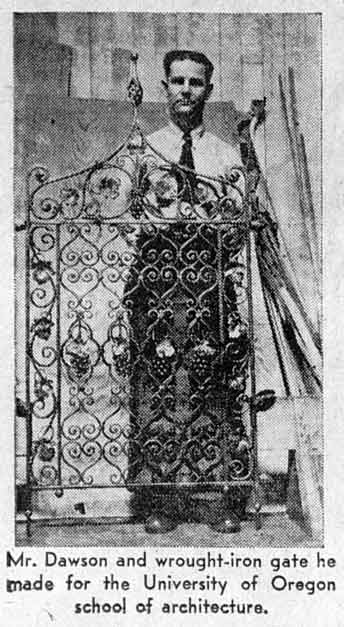

The WPA workshop was set up with Dawson in charge, and from this shop have since come such work as the beautiful Hall Memorial gates at the University of Oregon library; the massive five by 10-foot door at Timberline lodge; the 800 pound brass and bronze weathervane towering 30 fee into the air above the lodge; the 1100-pound inside gates of the lodge, the many hammered iron hardware pieces, furniture, and fixtures that add to the ruggedness of the new resort.

" Playing with wrought iron is not and easy task," Dawson admits. "It takes a real blacksmith to handle these jobs. Every inch of a pair of gates has to be beaten into shape and punched while red hot. Iron can be hammered wile cold, but in order to obtain the desired soft appearance, it must be heated. Few people realize the time and care that go into producing a fin piece of wrought iron work. Plans must be drawn actual size then all work is done by hand with great pains. That is why it makes such work expensive. Only those of considerable means can afford wrought iron gates of their own."

The Portland shop gives employment to a number or men. Some 16 workers are now engaged in completing the Oregon State college main entrance gates and the Howe Field fence, During the lodge construction approximately 40 iron workers were employed in the shop.

There is little difficulty in getting groups such as colleges and universities to meet the WPA requirements to furnish funds for materials. Dawson says, if the WPA will continue to provide costs for labor.

Mr. Dawson now dreams of a beautiful double-gate main entrance to the University of Oregon campus centered about a huge pylon on 13th street, and he sees future possibilities of other outstanding monuments of iron in Oregon.

The Oregon Sunday Journal - Portland

Probably December 11, 1938

(before 12/13/38)

Click HERE for scanned image of article (93K).